Ever found yourself staring at a dishwasher that just refuses to cooperate—leaking, not cleaning, or making strange noises—and felt that wave of helplessness? I’ve been there more times than I care to admit. One day, I realized that my frustration was often a result of not knowing the right diagnostic steps or having the right parts at hand. That lightbulb moment changed everything for me. Instead of rushing to replace the whole machine or wasting hours troubleshooting blindly, I started focusing on understanding key diagnostic tips and sourcing the right parts. It’s like giving your repair toolbox a serious upgrade, and trust me, it makes a world of difference.

Why Focusing on Diagnostics and Parts Matters More Than Ever

In 2025, the landscape of appliance repair is shifting fast. With newer dishwasher models packed with smarter tech, understanding the core diagnostic principles and having access to reliable parts is critical. Did you know that according to a recent industry report, over 70% of dishwasher failures can be traced back to just a handful of common issues? That’s a huge opportunity to save time and money if you know what to look for. Plus, with the rise of DIY repair culture, having a solid grasp on diagnostics is almost a necessity. If you’ve ever been tempted to skip the troubleshooting phase and jump straight to parts swapping, I urge you to reconsider. Making early mistakes—like replacing the wrong component—can be costly and frustrating.

Got this problem too? You’re not alone.

Trust me, I’ve made my fair share of mistakes, especially early on. I once replaced a perfectly good control board because I thought it was the culprit—only to find out it wasn’t. That’s why I started digging into expert diagnostics tips and focusing on the most effective parts for quick repairs. If you want to avoid wasting time and money, mastering these diagnostic strategies is your best bet. For a comprehensive guide to the top diagnostic parts and tips, check out this resource. It’s packed with practical advice and insider secrets that can save you hours of headaches.

Now that I’ve shared my story and why diagnostics are vital, let’s dive into the core techniques that will make you a dishwasher repair pro in 2025. Whether you’re a seasoned repair tech or a determined DIY enthusiast, these tips will help you troubleshoot smarter and replace parts faster. Ready? Let’s go!

Diagnose Like a Pro

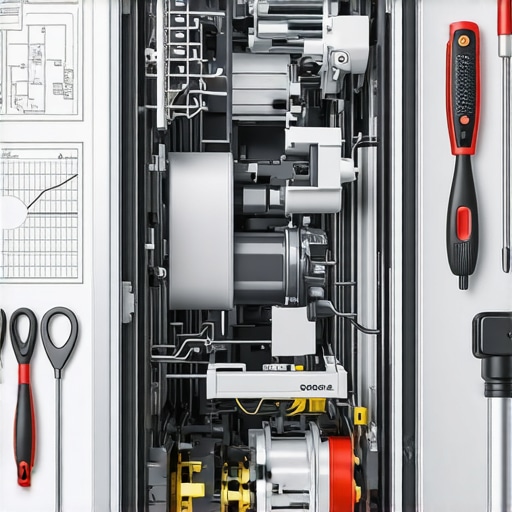

Start by isolating the problem. For leaks, check the door seal and hoses. Noticing poor cleaning? Focus on the spray arms and filters. I vividly recall a time when I faced a dishwasher that wouldn’t drain. Instead of randomly replacing parts, I followed a step-by-step diagnostic: first listening for unusual noises, then inspecting the drain pump and its connections. This methodical approach saved me hours and unnecessary part swaps. To deepen your diagnostic skills, explore these expert tips. They guide you through common failure points and how to identify them efficiently.

Source the Right Parts Fast

Once you pinpoint the issue, selecting the correct replacement parts becomes crucial. Think of your dishwasher as a car engine—each part has a specific function, and using an incompatible component is like putting the wrong spark plug in. When I needed a new circulation pump, I used the top diagnostic parts guide for 2025 to find a compatible, high-quality pump. Prioritize OEM parts or trusted aftermarket equivalents to ensure longevity and performance. Keep a well-organized parts list based on common failures, so you can grab what you need quickly during a repair.

Use Diagnostic Tools Effectively

Invest in a multimeter and learn how to test electrical components accurately. For example, testing the continuity of the drain solenoid or checking voltage at the control board can reveal hidden faults. I remember a case where I suspected the control board was dead—turned out, a fuse had blown. Using a multimeter saved me from unnecessary replacements. For detailed testing procedures, refer to these diagnostic strategies. They help you interpret readings correctly and avoid guesswork.

Prioritize Common Failure Points

Focus your efforts where failures most frequently occur. For dishwashers, these include the door latch, water inlet valve, and spray arms. During my last repair, I replaced a worn-out door latch, which resolved the leak instantly. To ensure you don’t overlook critical components, review the ultimate diagnostic parts list for 2025. This resource highlights the most common trouble spots and how to test them efficiently.

Document Your Repairs

Keep notes on what parts you tested, replaced, and the results. This habit accelerates future diagnostics and builds your repair confidence. I once fixed multiple dishwashers by tracking patterns in failures, which helped me streamline my approach. Use a simple spreadsheet or repair journal—whatever works for you—to record details. Over time, this data becomes a personal troubleshooting cheat sheet, making diagnostics faster and more accurate.

Stay Updated on New Tech

Smart dishwashers in 2025 come with sensors and IoT features. Learning how to interpret diagnostic codes and sensor data is essential. For instance, a malfunction indicator might point to a temperature sensor failure, which I diagnosed with a combination of code reading and physical testing. To stay ahead, regularly review latest repair strategies and upgrade your diagnostic toolkit. Keeping current ensures you’re ready for the most advanced models and their unique issues.

Many DIY enthusiasts and even seasoned repair techs fall into common traps when diagnosing dishwasher issues, often due to misconceptions about how appliances truly operate. Let’s dig deeper into some of these misconceptions and reveal the nuanced truths that can save you time and money. One widespread myth is that the control board is almost always the culprit when a dishwasher acts up. In my experience, this is rarely the case. Often, the control board appears faulty because it’s responding to sensor errors or peripheral component failures. Before jumping straight to replacing the control board, it’s crucial to verify other key parts like sensors, wiring, or switches. For reliable diagnostics, check out these expert tips.

Another common misconception is that newer, smarter dishwashers are immune to the basic issues that plagued older models. In reality, smart features add complexity, but many failures still revolve around fundamental parts such as the water inlet valve, spray arms, or drain pump. The nuance here is that smart models often have diagnostic codes that can mislead if you’re not familiar with their specific sensor data or error logic. For advanced troubleshooting, understanding these codes and sensor feedback is key. Review latest diagnostic strategies to navigate these complexities effectively.

What advanced troubleshooting mistakes do most people make without realizing?

One critical mistake is neglecting the importance of physical inspection alongside electrical testing. For example, testing a drain pump with a multimeter without inspecting the drain hose or filter can lead to missed issues like clogs or damaged hoses that are the root cause of drainage problems. This oversight is a trap because it can lead to unnecessary part replacements. Always combine electrical diagnostics with a thorough visual check. This integrated approach is a hallmark of expert troubleshooting. For comprehensive guidance, explore these diagnostic tips.

Have you ever fallen into this trap? Let me know in the comments. Remember, understanding the nuanced differences between symptoms and actual causes is what separates a quick fix from a costly mistake. Mastering diagnostics is about more than just replacing parts — it’s about knowing exactly what’s wrong and why, which ultimately leads to faster, more reliable repairs.

Maintaining your dishwasher over time requires a combination of the right tools and consistent care. Investing in quality diagnostic equipment, such as a digital multimeter, is essential for accurately testing electrical components like control boards, sensors, and switches. I personally prefer a reliable multimeter like the Fluke 117 because of its precision and durability, which makes troubleshooting much faster and more reliable. Additionally, having a set of small screwdrivers, pliers, and a flashlight helps me perform thorough inspections of hoses, filters, and seals—areas often overlooked but critical to long-term performance.

Beyond basic hand tools, I highly recommend using specialized diagnostic software if your dishwasher has smart features. Many modern appliances can be diagnosed via Wi-Fi with manufacturer apps, allowing you to access error codes and sensor data remotely. This proactive approach not only speeds up repairs but also helps in scheduling maintenance before minor issues turn into major breakdowns. As smart appliances become more prevalent, integrating these digital tools into your routine will become standard practice.

Regular cleaning and inspections are equally vital. I suggest setting a monthly schedule to check and clean spray arms, filters, and water inlet valves. Using a soft brush and a vinegar solution for mineral buildup keeps these parts functioning optimally. Don’t forget to inspect door seals for cracks or wear—replacing a worn seal prevents leaks and saves energy. Proper maintenance like this can extend your dishwasher’s lifespan significantly and reduce unexpected breakdowns.

Looking ahead, the trend in appliance maintenance points toward more integrated diagnostic systems and IoT sensors. These innovations will make it easier to identify issues early and even automate some repairs. For example, predictive maintenance algorithms could alert you to failing parts before they cause noticeable problems. To stay ahead, I recommend familiarizing yourself with the latest diagnostic techniques and tools, such as the comprehensive guides available at this resource. Incorporating advanced troubleshooting tips now will prepare you for the smarter appliances of tomorrow.

How do I maintain my dishwasher over time?

The key is consistency. Set a routine to inspect, clean, and test your appliance regularly. Use a multimeter to verify electrical connections and sensor outputs, ensuring each component functions correctly. Keep a detailed repair journal to track recurring issues and parts replacements—this record helps you spot patterns and avoid unnecessary repairs. Remember, staying proactive with maintenance not only prolongs your dishwasher’s life but also saves you money in the long run. For detailed diagnostics and maintenance strategies, check out these expert tips. Now, I challenge you to try testing your control board with a multimeter today—it’s a simple step that can prevent costly failures later!

The Hardest Lesson I Learned About Dishwasher Troubleshooting

One of my biggest breakthroughs came when I realized that rushing to replace parts without proper diagnostics often leads to wasted time and money. The lightbulb moment was understanding that methodical testing and sourcing the right parts are essential for effective repairs. This lesson transformed my approach from guesswork to precision, saving me countless headaches.

My Essential Toolkit for Effective Dishwasher Repairs

Over the years, I’ve found that a quality multimeter like the Fluke 117 is invaluable for electrical testing, along with small screwdrivers, pliers, and a flashlight for visual inspections. I also rely on dedicated diagnostic guides, such as this comprehensive resource, which keeps me updated on the latest models and troubleshooting techniques. These tools and references are my trusted allies in any repair.

What You Can Do Today to Improve Your Repairs

Take action now by testing your dishwasher’s control board with a multimeter. It’s a simple step that can prevent costly failures later and boost your confidence. Remember, mastering diagnostics isn’t just about fixing appliances—it’s about building skills that last a lifetime. Your effort today can turn you into a repair pro faster than you think.