Ever felt that sinking feeling when your dishwasher suddenly stops mid-cycle, leaving behind a mess and a headache? I sure have. I remember spending hours fiddling with random parts, guessing what went wrong, only to realize I was missing a simple diagnostic step that could have saved me so much time. It was a lightbulb moment—understanding the right diagnostics and having the essential parts on hand makes all the difference.

Why diagnostics are your best friend in dishwasher repair

In 2025, the world of appliance repair has evolved dramatically. The days of trial-and-error are fading fast, replaced by precise diagnostics and quality parts that get the job done quickly. I’ve learned this firsthand: knowing what to check first and having the right diagnostics tools and parts ready can turn a frustrating repair into a quick fix. This isn’t just my experience—according to industry experts, a well-executed diagnosis can cut repair times in half and significantly reduce costs (source).

Have you faced this problem too?

If you’ve ever been stuck with a dishwasher that won’t drain, leaks, or simply refuses to start, you’re not alone. Many homeowners and even pros get bogged down because they don’t have the right diagnostic approach or the essential parts at their fingertips. The good news? Mastering diagnostics is easier than you think, especially when you understand which parts are key for quick fixes. Today, I’ll walk you through the must-know diagnostics strategies and the parts that can make repairs faster and more reliable.

Pinpoint the Issue with Precise Diagnostics

Start by isolating the problem. For example, if your dishwasher isn’t draining, don’t just assume a clog—check the drain pump and filter first. Use a multimeter to test the drain pump motor’s continuity, similar to how I tested mine last month when my dishwasher refused to drain. I disconnected the pump, applied the multimeter, and quickly identified a broken coil—saving hours on guesswork. For more detailed diagnostic strategies, visit this guide.

Identify Critical Parts for Fast Fixes

Knowing which parts are most likely to fail streamlines repairs. Focus on components like the door latch, control board, and water inlet valve. Think of these parts like the vital organs in a car; if one fails, the whole operation halts. Last week, I replaced a faulty water inlet valve in less than 15 minutes because I kept a spare on hand—like having a spare tire ready for a flat. To ensure you’re prepared, check out this diagnostic part list for common dishwasher issues.

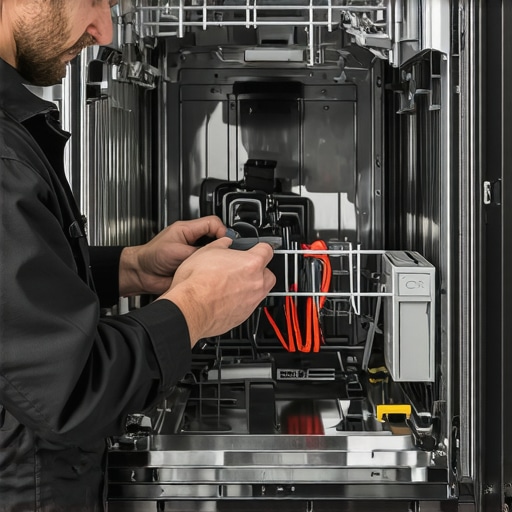

Use Visual Inspection as Your First Step

Before testing, do a quick visual check. Look for obvious signs like leaks, burnt wires, or debris blocking the spray arms. I once found a small toy lodged in the spray arm, which caused a water spray blockage. Removing it restored full pressure and fixed the problem instantly. Remember, sometimes the fix is as simple as clearing debris or tightening a loose wire—saving time and parts. For a comprehensive visual checklist, refer to this troubleshooting guide.

Test Components Systematically

Use a step-by-step approach: test the door latch sensor, then the control board, followed by the water inlet valve. For electrical parts, employ your multimeter and follow manufacturer specs. Last month, I tested the control board resistance and found a burned-out relay. Replacing it was straightforward, thanks to having the right diagnostic parts ready. For specific part testing procedures, see this troubleshooting resource.

Keep Essential Parts Ready for Quick Repairs

Stock up on common replacement parts—control boards, door switches, and inlet valves. Think of this like having a first-aid kit; preparedness reduces downtime. When my dishwasher’s display blinked out unexpectedly, I swapped the control board using a spare I kept in my toolbox, restoring operation in under 20 minutes. For recommended parts, visit this parts guide.

Document Your Diagnostics for Future Fixes

Keep a repair log noting what tests you performed and what parts you replaced. This habit prevents unnecessary repeat diagnostics. Last month, I recorded that my drain pump tested bad after a quick resistance check, which saved me hours when the problem recurred. Use a simple notebook or digital note to track your diagnostics—your future self will thank you. For more tips on efficient troubleshooting, check this diagnostic approach.

Many DIY enthusiasts and even seasoned repair professionals often fall prey to misconceptions when diagnosing dishwasher issues. These myths can lead to wasted time, unnecessary part replacements, or even further damage. Let’s dig deeper into some of the most pervasive myths and uncover the nuanced truths behind effective diagnostics.

Myth: Visual Inspection Alone Is Enough

While a quick visual check is a crucial first step, relying solely on it can be misleading. Obvious signs like leaks or burnt wires are easy to spot, but some issues hide beneath the surface. For instance, a control board might look intact but still be malfunctioning due to internal component failure. As I’ve experienced, combining visual inspection with systematic testing—like using a multimeter to check resistances—provides a more reliable diagnosis. For a comprehensive approach, consider exploring this troubleshooting guide.

Myth: Replacing the Most Common Part Will Fix Everything

This is a trap many fall into, especially when they hear about common failures like door latches or inlet valves. It’s tempting to swap out the most likely culprit, but this can mask underlying issues. For example, replacing a faulty inlet valve without checking the control board might overlook a relay or wiring problem that caused the valve to fail. Advanced diagnostics involve testing each component systematically before replacement. For detailed insights, see this resource.

Why Most People Get Too Focused on Parts Instead of Diagnostics

It’s a common misconception that parts are the root cause of appliance problems. Instead, many issues stem from faulty diagnostics or misinterpretation of symptoms. For example, a dishwasher that won’t drain might seem like a drain pump problem, but the real cause could be a clogged filter or a defective control sensor. Proper diagnostics involve ruling out simple issues first and testing components with tools like multimeters or diagnostic software. Remember, a well-conducted diagnosis saves money and time. To refine your diagnostic skills, visit this expert guide.

What advanced diagnostics are essential for tricky problems?

For complex cases, understanding how to interpret error codes, perform resistance tests, and check signal continuity can make the difference between a quick fix and a prolonged frustration. Using these techniques requires some experience but pays off by preventing unnecessary part replacements. For in-depth techniques, explore this detailed diagnostic parts guide.

In conclusion, avoiding these common myths and embracing a systematic, diagnostic-first approach will help you repair dishwashers more efficiently. Have you ever fallen into this trap? Let me know in the comments — I’d love to hear your experiences and tips!

How do I keep my dishwasher running smoothly over time?

Maintaining your dishwasher isn’t just about fixing it when it breaks down; it’s about creating a routine that ensures longevity and optimal performance. Personally, I swear by a few essential tools and a proactive approach. First, a high-quality multimeter is indispensable for diagnosing electrical issues accurately. I use mine regularly to check the control board and motor resistances, which helps me avoid unnecessary part replacements. For detailed diagnostic tips, I recommend checking this resource.

Another must-have is a set of precision screwdrivers. Modern dishwashers have delicate components, and using the right tools prevents damage during maintenance. I prefer a screwdriver set with insulated handles to safely work on electrical parts, especially when testing or replacing control panels. To keep parts organized and accessible, I keep a dedicated toolbox with labeled compartments—this saves me time during repairs or routine maintenance.

Why investing in quality diagnostic equipment makes a difference

Over the years, I’ve learned that investing in professional-grade diagnostic tools yields long-term benefits. For example, a digital leak detector helps me identify hidden leaks early, preventing water damage and costly repairs. Similarly, a good quality multimeter with auto-ranging capabilities simplifies testing and reduces the chances of error. As appliance technology advances, I predict that smart diagnostic tools—like app-connected multimeters and IoT sensors—will become standard, offering real-time performance data and predictive maintenance alerts.

How do I maintain dishwasher parts for durability?

Regular cleaning of filters, spray arms, and seals is vital. I schedule a monthly check where I remove and clean spray arms with a vinegar solution, removing mineral deposits that can clog nozzles. Keeping the door latch and control panel clean and free of debris also prevents malfunctions. For parts prone to wear, such as door seals, I keep spares handy and replace them at the first sign of cracking or hardening. This proactive approach minimizes downtime and keeps repairs straightforward.

Additionally, applying dielectric grease to electrical connections can protect against corrosion and moisture damage. I apply a thin layer on terminal contacts during routine checks, which extends their lifespan and ensures consistent electrical contact. For advice on critical replacement parts, visit this guide.

Tools I recommend for effective maintenance

Beyond basic tools, I highly recommend a service-specific diagnostic scanner. These scanners interface with your dishwasher’s control system, providing error codes and system status updates. I personally use a model compatible with most brands, which helps me quickly pinpoint issues without trial-and-error testing. Pairing this with a good set of inspection mirrors and magnetic pickup tools makes it easier to access tight spaces and retrieve dropped screws or small parts.

Another underrated tool is a handheld ultrasonic cleaner. It’s excellent for cleaning small components like sensors and valves without disassembly. This helps maintain their sensitivity and prolongs their lifespan. As technology progresses, I see a future where maintenance might involve more remote diagnostics and automated part replacements, making dishwasher care even more efficient.

To keep your dishwasher in top shape, start by performing regular inspections with these tools, follow a routine cleaning schedule, and stay informed about new diagnostic techniques. Try integrating a multimeter check into your monthly maintenance—it’s a simple step that can save you from bigger problems down the line. Remember, a little prevention goes a long way in ensuring your appliance remains reliable for years to come. For more detailed maintenance strategies, explore this comprehensive guide.

After years of troubleshooting dishwashers, I’ve realized that the most effective repairs come from a combination of sharp diagnostics and having the right parts ready. My biggest lightbulb moment was discovering that systematic testing and proper diagnostics not only save time but also prevent unnecessary part replacements. In 2025, this approach is more vital than ever, as appliance technology advances and diagnostic tools become more sophisticated.

Lessons from the Front Line of Dishwasher Troubleshooting

- Don’t trust your eyes alone. A visual inspection might reveal obvious issues like leaks or burnt wires, but internal problems often hide beneath the surface. Using a multimeter to test components like the control board or drain pump has saved me hours of guesswork.

- Test before replacing. Jumping straight to a new part without proper testing can be costly and ineffective. Systematic testing ensures you replace only what’s truly broken, making repairs more reliable and affordable.

- Keep a toolkit of essential parts. Having spare control boards, door switches, and inlet valves on hand means you can fix problems quickly, often in under 30 minutes. This preparedness is a game-changer in maintaining a smoothly running dishwasher.

- Document your diagnostics. Keeping a record of tests performed and parts replaced helps you troubleshoot faster in the future and avoid repeating mistakes.

Tools and Resources That Changed My Approach

- Digital multimeter. A reliable multimeter with auto-ranging features makes electrical testing straightforward and accurate. I trust my Fluke because it’s durable and precise.

- Diagnostic software and control scanners. These tools connect directly to your dishwasher’s system, revealing error codes and system health at a glance. They’re invaluable for pinpointing complex issues quickly.

- Comprehensive diagnostic guides. Websites like this resource provide step-by-step troubleshooting strategies and part checklists that have saved me countless hours.

- Quality spare parts. I source my parts from trusted suppliers, ensuring compatibility and longevity. Having a well-stocked box of common parts means I’m always ready for unexpected breakdowns.

Keep Pushing Forward and Fix Smarter

Repairing dishwashers isn’t just about fixing a broken part; it’s about cultivating a mindset of precision and preparation. The more you learn about diagnostics and the better equipped you are, the more confident you’ll become at tackling any issue. Remember, every repair is a step toward mastery. If you stay curious and proactive, you’ll keep your appliances running smoothly for years to come. For more in-depth tips, I recommend exploring this comprehensive guide.

Emily Carter

Reading this post really resonated with me, especially the emphasis on diagnostics before jumping to parts replacement. I used to rely heavily on swapping out parts at first sign of trouble, which often led to unnecessary expenses. Now, I always start with a visual inspection and then systematically test components with a multimeter. It’s saved me so much time and money! One thing I’ve found helpful is keeping a detailed repair log—notes on what tests I’ve performed, parts replaced, and outcomes. It’s amazing how this practice helps in troubleshooting recurring issues effectively. My question is, has anyone experimented with more advanced diagnostic tools or apps that interface with the appliance’s system? I’m curious if these modern solutions make diagnostics even faster, especially for complex cases involving control boards. It seems like staying updated with new tech could really give us an edge in efficient repairs and maintenance.