My Unexpected Journey into Dishwasher Troubleshooting

It all started last summer when my trusty dishwasher suddenly stopped working right before hosting a dinner party. Frustrated but determined, I dove into diagnosing the problem, quickly realizing that understanding the best dishwasher parts and diagnostics could save me both time and money. Over the years, I’ve learned that being familiar with key components makes all the difference in quick repairs.

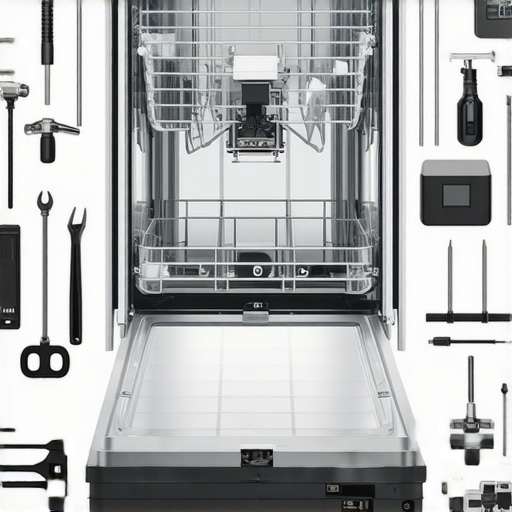

Discovering the Heart of the Dishwasher: Essential Parts I Trust

When I opened up my dishwasher, I found myself staring at a complex maze of parts. I quickly identified the float switch, control panel, and the circulation pump as critical elements to check. The Ultimate Dishwasher Diagnostics & Parts Guide became my go-to resource, highlighting the importance of these parts for reliable diagnostics. Knowing which components are likely to fail helps me prioritize repairs and avoid unnecessary replacements.

Mastering Diagnostics: The Key to Fast Fixes

My biggest breakthrough was learning how to run effective diagnostics. By listening for unusual noises or observing error codes, I could pinpoint issues faster. For example, a clogged spray arm or faulty door latch can cause major problems, and diagnosing these quickly saves hours of guesswork. I’ve found that tools like multimeters and diagnostic software are invaluable in this process. For more detailed troubleshooting techniques, I often consult the Dishwasher Troubleshooting Tips page, which provides step-by-step guidance.

Why Are Reliable Parts So Crucial?

I used to think cheap parts would suffice, but experience has taught me otherwise. When I replaced a faulty motor with a genuine part, my dishwasher ran smoother and lasted longer. It’s tempting to cut costs, but quality replacement parts, especially from trusted brands, ensure durability and reduce the likelihood of recurring issues. This insight aligns with advice from industry experts, emphasizing the importance of choosing the right parts for longevity.

What About the Future of Dishwasher Repairs?

Looking ahead to 2025, I believe that advancements in diagnostic technology will make repairs even easier. Smart sensors and IoT integrations are starting to detect issues early, guiding homeowners through repairs more effectively. As I continue to explore these innovations, I recommend staying updated with authoritative sources like Dishwasher Parts & Diagnostics to keep ahead in maintenance skills.

Ever wondered how to troubleshoot your dishwasher like a pro?

If you’re curious about more detailed diagnostic steps or specific replacement parts, I encourage you to explore the comprehensive guides linked throughout this post. Sharing your experiences or asking questions helps build a community of smarter DIY repair enthusiasts!

Unveiling the Hidden Diagnostics of Dishwasher Repairs

Understanding the nuanced diagnostics of dishwashers can significantly impact the success and speed of repairs. For instance, recognizing the significance of error codes and their corresponding components can save hours of troubleshooting. As I delved deeper into these diagnostics, I realized that tools such as multimeters and specialized diagnostic software are indispensable. These tools help verify electrical continuity and functionality of parts like the control board and sensors, which are often culprits in malfunction scenarios.

How Do Advanced Diagnostic Techniques Elevate Your Repair Skills?

Advanced diagnostics involve more than just basic checks; they require a deep understanding of how components interact and fail. For example, inspecting the wiring harness and connectors for corrosion or damage can reveal issues that simple part replacements might miss. Incorporating data from diagnostic modes, available on many modern dishwashers, allows for pinpoint accuracy in repairs. Exploring resources like oven repair diagnostics can provide transferable insights applicable to dishwasher troubleshooting as well.

Have you considered how the quality of replacement parts influences diagnostic accuracy?

Using genuine or high-quality aftermarket parts ensures that diagnostic signals and operational responses mirror the original design. This minimizes false positives during troubleshooting and enhances the longevity of repairs. For example, a faulty circulation pump might be diagnosed as a control issue if the replacement part is subpar, leading to unnecessary additional repairs. Trusted brands and verified suppliers are crucial, and consulting authoritative sources such as dishwasher diagnostics guide can help in selecting the right components.

What Are the Practical Challenges in Implementing Expert Diagnostic Strategies?

While advanced techniques offer precision, they also present challenges, such as the need for specialized knowledge and equipment. For DIY enthusiasts, understanding electrical schematics and learning how to interpret diagnostic codes can be daunting. However, these challenges are surmountable with detailed guides and community support. For example, resources like dishwasher troubleshooting tips provide step-by-step instructions that bridge the gap between theory and practice. Developing a systematic approach—checking error codes, testing components, and verifying wiring—can streamline diagnostics and prevent oversight.

Looking Ahead: How Will Future Innovations Transform Dishwasher Diagnostics?

The future of appliance diagnostics is poised for significant evolution, driven by smart technology and IoT integration. Imagine dishwashers equipped with sensors that automatically detect issues and suggest targeted repairs via smartphone apps. This integration could drastically reduce downtime and improve repair accuracy. Staying informed about these advancements is vital; trusted sources like dishwasher parts and diagnostics will be essential for both professionals and DIY enthusiasts seeking to adapt to these innovations.

Interested in deepening your diagnostic expertise? Share your experiences or ask questions in the comments—building a community around expert troubleshooting benefits everyone!

Unlocking the Nuances of Modern Dishwasher Diagnostics

As I continued to delve into the intricacies of dishwasher repairs, I realized that mastering diagnostics involves more than just checking error codes or swapping parts. It requires a keen eye for detail and an understanding of how subtle electrical and mechanical interactions can influence overall performance. For instance, I found that inspecting wiring harnesses for corrosion or loose connections often reveals hidden issues that simple component tests might overlook. These micro-issues can be the root cause of recurring malfunctions, and catching them early saves a lot of frustration.

How Do Diagnostic Tools Elevate Repair Precision?

Using advanced diagnostic tools like multimeters, oscilloscopes, and even specialized software transforms guesswork into science. I remember when I first started using a multimeter to verify circuit continuity; it was a game-changer. These tools allow me to verify voltage drops, check for shorts, and ensure that control boards are functioning within specifications. Moreover, integrating diagnostic software that communicates directly with the appliance can provide real-time data and error logs, pinpointing issues with remarkable accuracy. For those interested in expanding their toolkit, I recommend exploring resources like oven repair diagnostics, which, although focused on ovens, shares principles applicable to dishwashers.

What Are the Challenges of Interpreting Complex Diagnostic Data?

One of the most nuanced aspects of advanced diagnostics is interpreting complex data sets. Sometimes, error codes or sensor readings seem contradictory, leading to confusion. For example, a dishwasher might display an error indicating a circulation pump failure, but the pump tests fine—yet the problem persists. This discrepancy often points to issues in the control board or wiring. My approach is to systematically verify each component’s signals and look for inconsistencies or anomalies. Developing this analytical skill takes time but pays off in faster, more accurate repairs.

Have you wondered how the quality of replacement parts impacts diagnostic accuracy?

Absolutely. Using genuine or high-quality aftermarket parts is essential because subpar components can generate false error signals or fail prematurely. For example, a counterfeit circulation pump might cause irregular flow, confusing diagnostic systems and leading to unnecessary replacements. Relying on trusted brands and verifying suppliers—something I learned from consulting dishwasher diagnostics guide—ensures that diagnostic results are meaningful and that repairs stand the test of time.

Are There Hidden Diagnostic Strategies That Can Save You Time?

Yes, absolutely. One strategy I adopted is ‘divide and conquer’—breaking down the dishwasher into sections and testing each one methodically. For instance, I start with water intake and drainage, then move to spray arms and sensors, and finally review the control board and wiring. This layered approach avoids missing hidden issues. Additionally, I’ve found that keeping detailed logs of previous repairs and error patterns helps me recognize recurring problems faster. Sharing these insights with the community, or consulting comprehensive guides like dishwasher troubleshooting tips, has exponentially increased my repair efficiency.

What Future Innovations Will Revolutionize Dishwasher Diagnostics?

The horizon looks promising. IoT-enabled dishwashers with smart sensors will soon provide diagnostic data directly to our smartphones, offering real-time alerts and troubleshooting guidance. Imagine having your dishwasher notify you of a clogged filter or failing sensor before it causes a complete breakdown. Staying ahead of these trends involves not just adopting new tech but understanding its diagnostics, which is why I keep an eye on authoritative sources like dishwasher parts and diagnostics. Embracing these innovations will ultimately make repairs more straightforward and less time-consuming.

If you’re passionate about elevating your repair skills, I invite you to share your experiences or ask questions in the comments. Building a community of well-informed DIY enthusiasts benefits everyone and helps us stay prepared for the sophisticated appliances of tomorrow!

Harnessing the Power of Electrical Schematics for Precision Diagnostics

Delving into the realm of sophisticated diagnostics, I’ve discovered that mastering electrical schematics can dramatically enhance repair accuracy. These detailed diagrams unveil the intricate pathways of current flow and component interactions, allowing me to pinpoint faults that aren’t immediately obvious. For instance, when dealing with elusive control board failures, cross-referencing schematics with real-time voltage measurements helps identify subtle wiring issues or faulty connections. This approach requires patience and a keen eye but ultimately saves countless hours and prevents unnecessary part replacements. To deepen your understanding, exploring resources like oven repair diagnostics can provide transferable insights into complex electrical troubleshooting.

Integrating IoT and Smart Sensors: The Next Frontier in Diagnostic Accuracy

Looking ahead, the integration of IoT technology into dishwashers promises to revolutionize diagnostics. Smart sensors embedded in various components can monitor performance metrics in real-time, transmitting data to smartphone apps for instant analysis. This means that potential issues—such as declining water pressure or sensor malfunctions—are detected early, often before users notice any problem. Implementing these innovations involves understanding how to interpret digital signals and sensor outputs accurately. Staying updated with authoritative sources like dishwasher parts and diagnostics will be crucial for adapting to this evolving landscape. As DIY enthusiasts, embracing these tools can elevate our repair game from reactive fixes to proactive maintenance.

What Are the Challenges of Interpreting Complex Diagnostic Data?

One of the most nuanced aspects of advanced diagnostics is deciphering complex data sets, especially when error codes or sensor readings appear contradictory. For example, a dishwasher might report a circulation pump failure, yet physical tests show the pump is operational. This discrepancy often points to issues within the control board or wiring harness. My approach is to systematically verify each signal, cross-check with known good components, and utilize diagnostic software that provides detailed logs. Developing this analytical skill can be daunting but is essential for accurate troubleshooting. For further guidance, consulting oven repair troubleshooting can offer valuable parallels applicable to dishwasher diagnostics.

How Do High-Quality Replacement Parts Impact Diagnostic Confidence?

The importance of using genuine or certified aftermarket parts cannot be overstated, as subpar components can generate misleading error signals or fail prematurely. For instance, a counterfeit circulation pump may cause irregular water flow, confusing diagnostic tools and leading to unnecessary replacements. Ensuring compatibility and quality by sourcing from trusted suppliers—guided by insights from dishwasher diagnostics guide—is paramount. Accurate diagnostics depend on components that behave as expected, enabling precise fault localization and durable repairs.

Are There Hidden Diagnostic Strategies That Offer a Competitive Edge?

Absolutely. One technique I’ve adopted is the ‘divide and conquer’ approach—breaking down the dishwasher into manageable sections and testing each systematically. Starting with water intake, then moving to drainage, spray arms, sensors, and finally the control board, this layered method prevents oversight of micro-issues. Additionally, maintaining detailed logs of error patterns and previous repairs accelerates problem recognition. Sharing these strategies within a community or consulting comprehensive guides like dishwasher troubleshooting tips has significantly improved my troubleshooting efficiency and confidence.

What Future Innovations Will Redefine Diagnostic Capabilities?

The horizon is bright with innovations like AI-powered diagnostic algorithms and enhanced sensor technologies. Imagine dishwashers equipped with predictive maintenance capabilities, alerting users to issues before they manifest as faults. These advancements will shift our role from reactive repair to predictive upkeep, minimizing downtime and repair costs. Staying ahead involves continuously learning from sources like dishwasher parts and diagnostics and embracing emerging technologies. As DIY repairers, cultivating familiarity with these tools and trends ensures we remain effective and relevant in this rapidly evolving field.

If you’re passionate about mastering these advanced diagnostic techniques, I invite you to share your experiences or ask questions. Engaging with a community of enthusiasts helps us all refine our skills and tackle even the most complex appliance issues with confidence.

Things I Wish I Knew Earlier (or You Might Find Surprising)

The Power of a Good Diagnostic Routine

One thing I’ve learned over the years is that developing a systematic diagnostic approach saves a ton of time. Early on, I’d randomly swap parts, which led to unnecessary expenses. Now, I always start with error codes and basic tests, which quickly point me in the right direction. It’s like having a GPS for repairs—so much more efficient!

Genuine Parts Make All the Difference

I used to think cheap replacements would do the job, but I’ve found that genuine or high-quality aftermarket parts are crucial for long-term reliability. For example, installing a genuine circulation pump reduced recurring issues and kept my dishwasher running smoothly for years. Trusting reputable brands is worth the extra effort.

Understanding Electrical Schematics is a Game Changer

Getting comfortable with wiring diagrams and schematics might seem intimidating at first, but it’s a skill that pays off. When I had control board issues, cross-referencing schematics helped me identify subtle wiring faults that visual inspection missed. It’s like having a secret decoder for complex problems.

Advanced Tools Elevate Your Troubleshooting

Using multimeters and diagnostic software transformed my repair process. I can now verify voltage levels, check continuity, and even read detailed error logs. These tools turn guesswork into precision, making repairs faster and more reliable. If you’re serious about DIY, investing in quality diagnostic equipment is a must.

The Future Is Smart and Connected

Looking ahead, I’m excited about IoT-enabled dishwashers that can diagnose issues and notify you via smartphone. Imagine early warnings about clogged filters or sensor failures before they cause breakdowns. Staying updated with these innovations ensures I’m prepared for smarter repairs.

Resources I’ve Come to Trust Over Time

- Appliance Repair Forum: An active community sharing real-world troubleshooting tips, which has helped me countless times.

- Manufacturer’s Service Manuals: Official guides that provide detailed electrical schematics and diagnostic procedures—my go-to for complex issues.

- Trusted Appliance Parts Suppliers: Reliable sources for genuine replacement parts, ensuring my repairs last.

- Online Diagnostic Guides: Websites like Ultimate Dishwasher Diagnostics & Parts Guide offer step-by-step troubleshooting that’s invaluable for DIYers.

Parting Thoughts from My Perspective

Mastering dishwasher diagnostics has been a rewarding journey. From understanding key parts to leveraging advanced tools, each step has made me more confident in handling repairs. Trust me, investing time in learning these skills pays off in cost savings and peace of mind. If this resonates with you, I’d love to hear your thoughts or experiences. Sharing knowledge helps us all become better DIY repair enthusiasts!

Rachel Green

Reading your detailed journey into dishwasher diagnostics really resonated with me. I recently had a similar experience where my dishwasher suddenly stopped mid-cycle, and I thought it was a major issue at first. After some research and using a multimeter, I discovered that a faulty control board was the culprit, which was a valuable lesson in the importance of understanding electrical schematics. One challenge I faced was interpreting error codes reliably, especially when the error seemed to indicate a different problem than what I observed.

I’m curious, how do others here approach diagnosing error codes that don’t match the actual symptoms? Do you rely mainly on hardware testing, or do you also use software diagnostics? I find combining both approaches often gives me the best results. Exploring sources like the troubleshooting guides you mentioned definitely helps build confidence—especially when dealing with complex component interactions. I’d love to hear if others have tips or tools that have made their troubleshooting more efficient, especially for those micro-issues that aren’t immediately obvious.

Michael Anderson

Your detailed post really sheds light on how essential a systematic approach is in troubleshooting dishwashers. I remember my own experience fixing a dishwasher that would randomly stop mid-cycle. Using the diagnostic tips and understanding the circuit paths through schematics made all the difference. One thing I’ve found helpful is keeping a repair log of error codes and how I fixed certain issues, which helps when similar problems come up later. I also agree that quality parts from trusted brands not only improve repair longevity but also make diagnostics more straightforward since the tools and signals behave as expected.

Regarding error codes that don’t seem to align with the observed problem, I’ve learned that sometimes the root cause can be an upstream issue, like a faulty sensor that triggers false codes. Have others tried inspecting and testing sensors or wiring connections when the error seems inconsistent? Also, do you use any particular diagnostic software or apps to assist with interpreting error logs? Sharing these insights could really help expand our troubleshooting toolkit, especially for micro-issues that are tricky to pin down without the right tools.

James Carter

Reading your detailed journey into dishwasher troubleshooting really struck a chord with me. Last summer, I faced a similar situation when my dishwasher stopped mid-cycle just before a family gathering. Like you, I found that understanding key parts like the control board and sensors made all the difference in diagnosing the problem efficiently. I also rely heavily on the diagnostic guides you mentioned, especially because error codes can sometimes be a bit ambiguous or misleading. I’ve learned that combining hardware tests with software diagnostics often leads to the quickest and most accurate results. For instance, I use a multimeter for electrical checks but also utilize some basic troubleshooting apps to interpret error logs. Has anyone here found particular tools or techniques especially helpful for micro-issues that aren’t immediately obvious? I find that keeping a repair log not only helps troubleshoot recurring problems but also speeds up the diagnosis process over time.