My Unexpected Dishwasher Dilemma and What I Learned

Last summer, I found myself facing an unexpected dishwasher failure just before hosting a family dinner. Like many homeowners, I initially panicked, wondering if I should call a technician or attempt a repair myself. That experience sparked my curiosity about effective diagnostic strategies and understanding the crucial parts involved in troubleshooting modern dishwashers.

How I Started My Diagnostic Journey

After some quick research, I realized that a systematic approach is essential for efficient troubleshooting. I learned that familiarizing myself with key diagnostic steps and the most common parts can save both time and money. To deepen my understanding, I turned to authoritative sources like expert diagnostic strategies, which provided valuable insights into identifying issues accurately.

What Are the Critical Diagnostic Strategies?

My first step was to check for simple causes, like clogged filters or a tripped circuit breaker. When these didn’t resolve the problem, I moved on to testing components like the motor, water inlet valve, and the control panel. I discovered that understanding how these parts function helps in pinpointing the root cause efficiently. For instance, if the dishwasher isn’t filling with water, the water inlet valve or float switch might be faulty. Diagnosing these parts requires a bit of patience and some basic tools, but the payoff is well worth it.

Which Parts Are the Most Common Troubleshooters?

From my experience, the water inlet valve, door latch, and control board frequently cause issues. Replacing these parts often restores the dishwasher’s functionality. I was surprised to find that many problems stem from simple electrical issues or worn-out mechanical components. For those interested in a more detailed parts guide, I recommend exploring expert diagnosis parts for faster repairs.

Why is understanding the inner workings of my dishwasher so important?

Knowing the function of each part not only helps in diagnosing problems but also empowers me to perform repairs confidently. It reduces dependency on costly technician visits and extends the lifespan of my appliances. Plus, staying informed about diagnostic strategies ensures I can handle future issues swiftly. If you’re curious about other repair tips, check out top diagnostic tips.

Sharing personal repair stories helps demystify appliance troubleshooting. If you’ve faced similar challenges, I encourage you to comment below or share your experiences. Together, we can build a community of savvy homeowners who troubleshoot with confidence!

How Can Understanding the Dishwasher’s Internal Mechanics Prevent Future Failures?

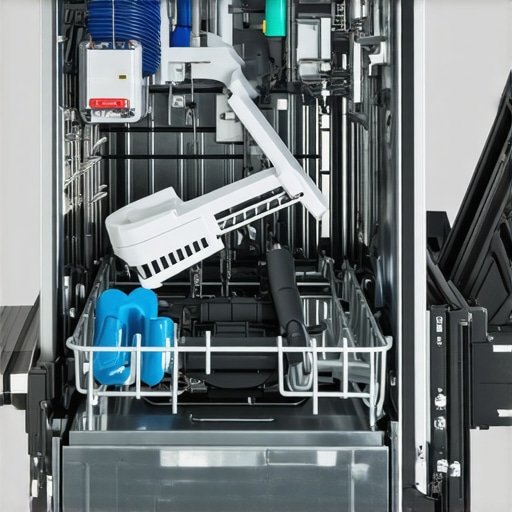

Delving into the inner workings of your dishwasher isn’t just about fixing a current problem — it’s a proactive approach to maintenance that can extend the appliance’s lifespan and prevent future breakdowns. By understanding how components like the pump, spray arms, and electronic control board interact, you gain insights into potential failure points. Regular inspection of parts such as the door latch, water inlet valve, and sensors can alert you to wear and tear before they cause costly repairs. For in-depth guidance on these crucial parts, explore expert diagnosis parts.

What Are the Nuanced Indicators That Signal a Need for Part Replacement?

While obvious signs like water pooling or failure to start are clear indicators of malfunction, subtle cues can reveal underlying issues. For instance, irregular cycle times or inconsistent cleaning results might point to a failing circulation pump or clogged filters. Similarly, unusual noises during operation could be linked to worn bearings or motor issues. Recognizing these nuanced signs allows for targeted diagnostics, saving time and resources. A comprehensive understanding of diagnostic strategies, including testing the control board and float switch, can be found at top diagnostic strategies.

How Do External Factors Influence Internal Component Wear and Tear?

External factors such as water quality, household voltage fluctuations, and frequency of use significantly impact the longevity of dishwasher parts. Hard water, for example, can cause mineral buildup in the water inlet valve and spray arms, leading to reduced efficiency. Voltage surges may damage electronic control modules, necessitating careful inspection and possibly additional surge protection. Understanding these influences prompts homeowners to implement preventative measures, like installing water softeners or surge protectors, which help maintain optimal functioning of critical components. For a detailed overview of common issues caused by external factors, see essential diagnostic tips.

What Are the Practical Steps to Conduct a Root Cause Analysis in Dishwasher Repairs?

Effective troubleshooting begins with a methodical root cause analysis. Start by documenting the symptoms, then systematically test components like the door switch, water inlet valve, and drainage pump. Use multimeters and diagnostic tools to verify electrical continuity and proper operation. When parts are identified as faulty, consult authoritative repair guides to determine whether a replacement or repair is best. Engaging with expert resources like diagnostic guides ensures precision and confidence in your repairs. Remember, understanding the interconnectedness of these parts is key to resolving complex issues efficiently.

If you’ve found these insights helpful, consider sharing your own troubleshooting stories or asking questions in the comments below. For more expert tips on appliance diagnostics, don’t miss our comprehensive articles on top diagnostic tips and oven repair diagnostics. Your experiences can help fellow DIY enthusiasts troubleshoot with greater confidence!

Reflections on the Hidden Complexities of Dishwasher Troubleshooting

Over the years, as I delved deeper into appliance repair, I realized that troubleshooting dishwashers is much more than just replacing faulty parts. It’s an intricate puzzle, where understanding the nuanced interplay between mechanical components and electronic controls can make all the difference. For instance, I once faced a dishwasher that refused to drain, and after inspecting the obvious culprits, I discovered that a minor blockage in the drain hose was masking a failing pump motor. This experience reminded me that sometimes, the smallest details—like a tiny debris buildup—can obscure the bigger picture, emphasizing the importance of meticulous inspection.

Unveiling the Layers of Diagnostic Complexity

What truly intrigued me was how external factors subtly influence internal component wear. Hard water, household voltage fluctuations, and even the frequency of use can accelerate wear on parts like the water inlet valve or control board. That’s why I now advocate for a holistic approach: regular maintenance, water softening treatments, and surge protection. I’ve found that preventive measures often save more time and money than reactive repairs. For those eager to go beyond basic troubleshooting, exploring expert diagnosis parts offers invaluable insights into preemptive diagnostics.

The Nuance of Subtle Diagnostic Signs

One of the most intellectually stimulating aspects of diagnosing dishwashers is recognizing the subtle cues. For example, irregular cycle times or inconsistent cleaning can hint at issues with the circulation pump or sensors. I recall a case where a dishwasher’s unusual noises during operation led me to discover a worn bearing that caused motor vibrations. These nuanced indicators require a keen eye and experience but can significantly streamline the repair process. Recognizing these signs early often prevents more extensive damage, preserving both the appliance and household budget. For in-depth strategies, I recommend reviewing ultimate diagnostic tips.

Connecting External Factors to Diagnostic Outcomes

External influences like mineral buildup or voltage surges often complicate diagnostics. In my journey, installing a water softener proved transformative in reducing mineral deposits in the water inlet valve and spray arms. Similarly, using surge protectors helped safeguard electronic control modules, extending their lifespan. These proactive measures reveal the importance of understanding the environment where appliances operate, which can dramatically improve diagnostic accuracy and repair longevity. Exploring essential diagnostic tips further deepens this understanding.

Deepening Knowledge Through Root Cause Analysis

Developing a systematic approach to root cause analysis has been pivotal. I now start by documenting symptoms meticulously, then verify each component with multimeters and diagnostic tools, following expert guides like diagnostic guides. This disciplined methodology helps me avoid guesswork and pinpoint the exact malfunction, whether it’s a failed float switch or a faulty control board. Sharing these experiences encourages others to adopt a methodical mindset, turning troubleshooting into a rewarding puzzle rather than a frustrating chore.

If you’ve encountered similar challenges or developed your own diagnostic techniques, I invite you to share your stories or ask questions below. Engaging with a community of DIY enthusiasts not only enriches our knowledge but also boosts confidence in tackling complex repairs. Keep exploring, keep learning—your next successful repair might be just a diagnosis away!

Deciphering the Complex Interplay of Mechanical and Electronic Components

As I delved deeper into the intricacies of dishwasher repair, I discovered that diagnosing issues often requires understanding the nuanced interactions between mechanical parts and electronic control systems. For instance, a dishwasher that fails to complete its cycle might be experiencing a subtle malfunction in the electronic control board, which, in turn, influences the operation of sensors, pumps, and valves. Recognizing these complex relationships enables me to approach troubleshooting with a more analytical mindset, reducing guesswork and increasing repair accuracy. This layered understanding is particularly vital when dealing with microcontroller-driven appliances, where a single faulty relay or sensor can cascade into multiple failures.

Advanced Diagnostic Techniques for Persistent or Intermittent Failures

When faced with elusive or intermittent problems, I employ advanced diagnostic tools like oscilloscopes and specialized multimeters to monitor signal integrity and voltage fluctuations in real-time. For example, diagnosing a dishwasher that randomly stops mid-cycle might involve checking the integrity of the control board signals or verifying sensor outputs during operation. Additionally, consulting authoritative sources such as expert diagnosis parts guides me through complex troubleshooting sequences, ensuring I don’t overlook hidden issues lurking within the circuitry.

How External Environmental Factors Accelerate Internal Component Wear?

External factors, particularly water quality, household electrical supply stability, and ambient conditions, significantly influence the longevity of internal dishwasher components. For instance, hard water deposits can cause mineral buildup in water inlet valves and spray arms, reducing flow efficiency and increasing strain on pumps. Voltage surges from unstable power sources can damage sensitive electronic modules, leading to premature failures. I’ve learned that implementing preventative measures—such as installing water softeners or surge protectors—not only extends the lifespan of parts but also facilitates more accurate diagnostics by minimizing external stressors. For a comprehensive overview of external influences, explore essential diagnostic tips.

Why Is It Crucial to Map the Interconnectedness of Internal Components?

Mapping the interconnected pathways within a dishwasher—how water flows, how electrical signals propagate, and how mechanical movements coordinate—is essential for pinpointing root causes efficiently. I often create detailed diagrams or mental models during diagnostics, which help me visualize potential failure points. For example, a communication breakdown between the control board and the water inlet valve might manifest as filling issues, but understanding the wiring diagram reveals whether the problem stems from a faulty relay, a broken wire, or the control module itself. This holistic perspective accelerates repairs and prevents unnecessary replacements, saving time and resources. For further insights, visit expert diagnosis parts.

How Can I Use Data Logging and Pattern Recognition to Improve Diagnostic Accuracy?

In my quest for precision, I utilize data logging devices and software to record operational parameters over multiple cycles. Recognizing patterns—such as a specific error code appearing only after a certain duration or under particular conditions—guides me toward more targeted diagnostics. For example, if a dishwasher intermittently fails to drain, logging the cycle data might reveal that the issue correlates with high water temperature or specific load configurations. Integrating these insights with diagnostic resources like ultimate diagnostic tips enhances my troubleshooting efficiency, enabling me to identify root causes with greater certainty.

Engage with My Deep Dive into Complex Diagnostics

If you’re eager to expand your diagnostic toolkit beyond basic troubleshooting, I invite you to explore my detailed experiences with persistent or complex dishwasher failures. Sharing your own diagnostic journeys or asking specific questions can foster a community of knowledgeable DIY enthusiasts. Together, we can unravel the most intricate appliance mysteries, turning complex failures into manageable challenges. Dive deeper into expert strategies and advanced diagnostics by visiting expert diagnosis parts. Your next breakthrough might be just a diagnosis away!

Things I Wish I Knew Earlier (or You Might Find Surprising)

1. Small Details Make Big Differences

During my repair journey, I learned that tiny debris or subtle noises often hide the root cause of problems. For example, a minor clog in the drain hose was masking a failing pump motor, showing me that meticulous inspections are crucial. Overlooking these small clues can turn simple fixes into major headaches.

2. External Factors Accelerate Wear

External influences like hard water and voltage fluctuations can significantly shorten the lifespan of components. Installing a water softener or surge protector has helped me prevent many breakdowns, proving that understanding your environment is key to smarter diagnostics.

3. Visualizing Interconnections Boosts Accuracy

Mapping out how parts like sensors, valves, and the control board connect has improved my troubleshooting. Creating diagrams or mental models helps pinpoint failures faster, saving time and unnecessary replacements.

4. Subtle Signs Can Warn of Future Failures

Unusual cycle times or inconsistent cleaning often hint at underlying issues. Recognizing these early signs allows me to perform targeted diagnostics, avoiding costly repairs down the line.

5. Regular Maintenance Is a Game Changer

Simple tasks like cleaning filters and inspecting spray arms regularly keep my dishwasher running smoothly. Preventive care minimizes unexpected failures and prolongs appliance life.

6. Environment Matters More Than You Think

Household water quality and electrical stability influence internal parts. Using water softeners and surge protectors has been invaluable in maintaining consistent performance and diagnosing problems accurately.